Phase transformations and structure evolution

The research is directed towards structural changes during processing, heat treatment and usage of metallic materials. The most important questions are: How will the structure transform under given conditions? How rapid is the transformation?

The research efforts are thus concentrated in the following major areas:

- Computer-operated analysis of the coupling between thermodynamics, phase diagrams and phase transformation kinetics of multicomponent alloys.

- Experimental and theoretical study of phase transformations during processing of metals and composites.

Fundamental aspects of phase transformations as well as more practical problems in heat treatment are studied. The fundamental work involves theoretical analysis of diffusional reactions and interfacial reactions in multicomponent alloys as well as partitionless transformations like the massive and martensitic transformations.

The work on diffusional reactions is directed towards the development of models of diffusion in complex materials and the compilation of a data bank comprised of diffusivities in multicomponent systems. In addition thermodynamic calculations based on THERMO-CALC are a most valuable tool in the theoretical analysis.

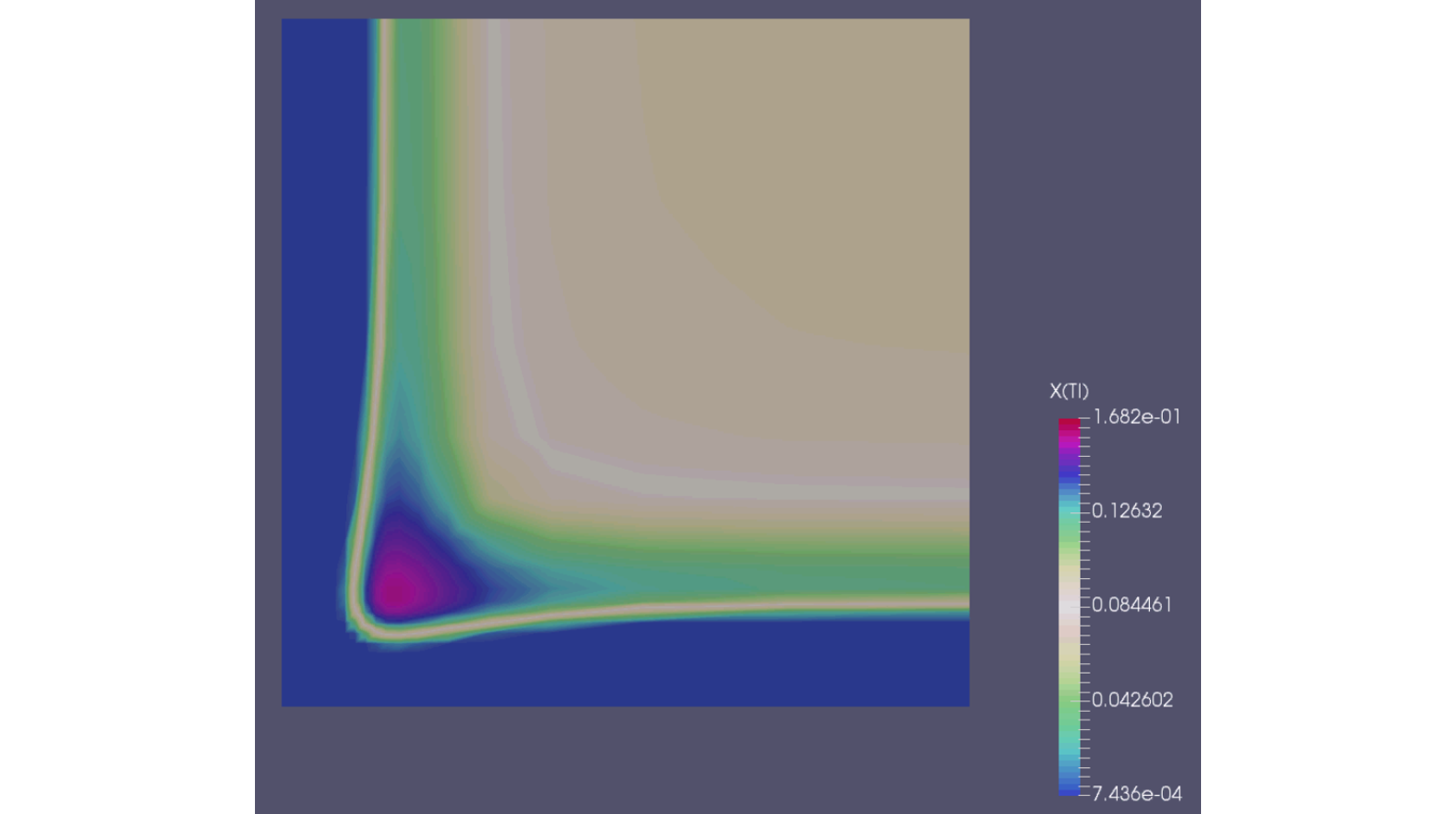

The kinetic modelling is done using sharp interface methods (e.g. using DICTRA), diffuse interface methods (i.e. phase field) on both fixed domains as well as with mean field approaches (e.g. using TC-Prisma).

The research is directed both towards the theoretical development of the methods and the numerical implementation of these into useful software. The methods generally aim at using thermodynamic and kinetic data obtained by Calphad assessments. The software used are both external and developed in-house.

The computer methods are applied in various projects concerning, for example, low-alloy as well as high-alloy steels, cemented carbides, super-alloys and coatings. The experimental work concerns the study of phase transformations by means of various metallographic techniques like light-optical microscopy, SEM, TEM, STEM, X-ray, DSC as well as measurements of magnetic properties.

The main emphasis is on structural materials where the research covers a wide range of metallic materials including steels and metal-matrix composites. However, a considerable effort is now made in the area of functional materials and involves shape memory alloys and magnetostrictive materials.