Alumni

The Hultgren Laboratory for Materials Characterisation was formed as a unit in early 2024 and so we now have several alumni. Here you can find out more about our alumni, the work that they did at our research unit, and what our alumni are doing now. We are delighted to be able to continue to work with our alumni.

Monika Rolinska, PhD, December 2025

In December 2025, Monika successfully defended her

PhD thesis

"Neutron Scattering-Based Characterisation of Early-Stage Phase Transformations - Applied to Duplex Stainless Steels and Related Systems". Monika's PhD was part of the Swedish graduate school on neutron scattering (SwedNess), where the school has the purpose of building capabilities in Sweden to use large scale neutron facilities for advanced research. The use of small angle neutron scattering (SANS), and development of data analysis methodoligies, was therefore a key aspect of Monika's research into how to slow ageing effects in duplex stainless steels.

During service, duplex stainless steels experience embrittlement at elevated temperatures which limits their service life time. Intermediate heat treatments have been proposed as a method for delaying embrittlement. Monika therefore invested the influence of heat treatment on material phases and properties by comparing traditional duplex steels and heat treated duplex steels - using SANS and other materials characterisation instruments and various theoretical models.

Findings were that intermediate heat treatments do reduce the onset of embrittlement.

Monika went on to assess the mechanisms leading to the delay of embrittlement using pair distribution function (PDF) analysis. Due to the bulk characteristics of the material, texture effects were found during the analysis of experimental data, which necessitated the development of a so-called large-box model for data analysis. Nonetheless, the influence of texture was so noteworthy that it limited the conclusions that could be drawn. However, findings for advancing the work in future were identified.

Virginia Morete Barbosa Bertolo, October 2025

Virginia joined us for a year as a post doctoral researcher.

As a Postdoctoral Researcher at KTH Royal Institute of Technology’s Hultgren Laboratory, Virginia addressed the impact of shearing processes, such as hole punching, on the fatigue behavior of advanced high-strength steels used in the automotive industry. She employed cutting-edge techniques such as Focused Ion Beam (FIB)'s Digital Image Correlation (DIC) and micro-mechanical testing. Via these techniques, she measured micro residual stresses and analysed strain partitioning. Such analysis is supporting the design of steels with improved fatigue resistance.

Her research interests include advanced materials characterisation, the relationship between processing, microstructure, and properties, and the study of fracture micro-mechanisms across length scales in metallic materials under extreme environments.

Virginia was offered a position within Allseas (

LinkedIN

), where she is using her expertise as a Materials Engineer.

Agathe Podolak, Intern, August 2025

Agathe joined us from Polytech Lille, France for a four month student mobility placement that was part of her Masters degree.

Agathe's project work with us was part of a larger activity within the NEXT Competence Centre to explore high-throughput x-ray measurements on the laboratory scale as well as the synchrotron scale. She received training in how to produce samples as well as use the Hultgren Laboratory's x-ray diffraction instrument. Agathe then went on to independently conduct her research activities. Her systematic and dilligent work produced interesting results, which merited inclusion in a scientific paper that is currently under preparation. Naturally, Agathe will be a co-author.

Stella Sten, PhD, June 2025

Stella’s interest in materials science started during her undergraduate studies at KTH, where a hands-on assignment - designing, making and testing a material - sparked her curiosity and eventually led her to pursue a PhD. In June 2025, Stella successfully defended her

PhD thesis

"Non-homogeneous structures in cemented carbides".

Stella's PhD explores how we can deliberately create non-homogeneous structures. This opens up possibilities to reduce the need for rare or critical raw materials while tailoring components to be stronger, harder, or more durable exactly where it’s needed.

Stella planned how functional gradients could be formed within a material. She assessed the factors affecting the gradients and how gradients affected material structures by combining advanced modelling with experiments - measuring structures at the nano, micro, and millimetre scales. Her findings contribute to developing more sustainable tool materials for demanding applications such as metal cutting or rock drilling, where combining high hardness and toughness is essential.

Towards the end of her PhD studies, Stella was offered a research position within Sandvik Coromant (

LinkedIN

). At Sandvik, she has already demonstrated her expertise in this field by securing her first patient. We are pleased to continue to collaborate with Stella via the

NEXT Competence Centre

and other iniaitives.

Márcio Freitas de Abreu, PhD, June 2025

In June 2025, Marco successfully defended his

PhD thesis

"Cavitation Erosion of Cast Irons in Engine Coolants- Interactions and Damage Mechanisms".

Marcio was an industrial PhD student, who worked with the Scania Group investigating how tiny bubbles lead to major material damage. This issue affects the durability of engine cooling systems and engines, especially in heavy-duty vehicles. While it was long believed that individual collapsing bubbles were the main source of material damage, Marcio's research tells a different story. His work highlights the crucial role of bubble clouds. When these clouds implode near a component’s surface, they generate powerful pressure waves that stress and damage the material. These insights, as well as Marcio's other findings, bring us one step closer to making vehicle components more robust and resistant to erosion.

Marcio's next step after his PhD is within the Scania Group (

LinkedIN

), where he will work further on his PhD findings. We hope to continue to collaborate with Marcio e.g. via initiatives in the

Center for Mechanics and Materials Design

and

NEXT Competence Centre

, where Scania are also active.

Nader Heshmati, PhD, January 2025

In January 2025, Nader successfully defended his

PhD thesis

"Effect of microstructure on pre- and post-punching fatigue behavior of hot-rolled thick-plate advanced high-strength steel".

With the aim of identifying a light-weight steel to replace the current materials used for chassis in heavy-duty trucks, Nader collaborated with Scania and SSAB via the Center for Mechanics and Material Design (

MMD

).

Using the Hultgren Laboratory's instruments, Nader's work focused on quantifying fatigue properties and relating these to the complex microstructures of the materials. He compared two new steels with the current material, examining their microstructures/performance both pre- and post- hole punching. He developed a good scientific understanding of the coupling between microstructure, static mechanical properties, fatigue crack initiation and fatigue crack propagation.

Nader is able to continue to research on his PhD topic at Swerim AB, Stockholm. (

LinkedIn

). We are pleased to be able to continue to work with Nader e.g. via the Steel4fatique research programme.

Bharat Mehta, PostDoc, 2024

Bharat's expertise is in alloy design, which was used to explore how to design recycling-friendly and scrap-tolerant steels. The approach used both high-throughput alloy modelling approaches as well as producing demonstration alloys - comparing the model predictions with actual microstructural characteristics and material design. This made extensive use of the instruments in the Hultgren Laboratory.

His publication "Toward Scrap-Tolerant Steels: Investigating the Role of Cu and Sn Micro-Segregations on Solidification Microstructure and Cracking" illustrates that we can make progress towards more use of scrap - while still producing quality alloys. (See more on

research gate

).

This project was funded by the Wallenberg Initiative Materials Science for Sustainability (

WISE

).

Bharat joined Thermo-Calc Software as an application specialist (

LinkedIn

). He is therefore still in touch with our research unit e.g. via the collaborations in the NEXT Competence Centre.

Gabriel Spartacus, PostDoc, 2024

Gabriel's expertise is in the use of synchrotrons and other large scale facilities. He joined us in 2021 to work in CeXS initiative i.e. to support the development of competences and the PETRA III Swedish Materials Science beamline's infrastructure.

Gabriel's contribution to infrastructure development is exemplified by the conceptual design and specifications of a

new hutch

at the PETRA III Swedish Materials Science beamline. This new hutch was conceived to support industrially-relevant sample environments and complement the existing hutch at the P21.1 branch.

Gabriel supported research via his practical skills in setting up and using complex sample environments. Another area of expertise was the analyse complex synchrotron data, exemplified by

this article

on precipation kinetics.

Gabriel now uses his research and infrastructure expertise at Swerim AB, Stockholm. (

LinkedIn

)

We are pleased to be able to continue to collaborate with Gabriel e.g. via his role as a Project Leader in the

NEXT

Competence Centre.

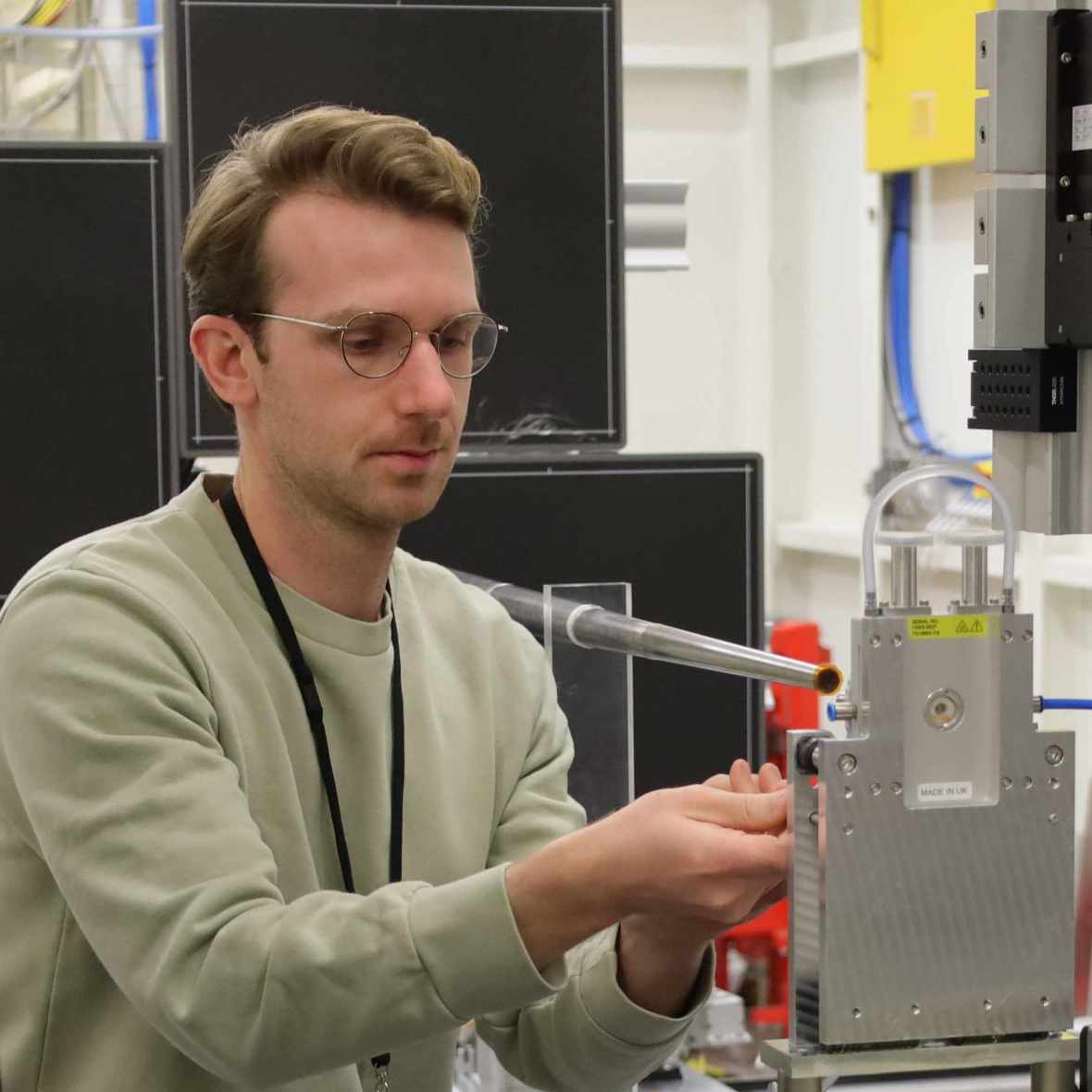

Tim Fischer, PostDoc, 2024

Tim's expertise is in micro mechanical modelling, expecially the emerging field of chrystal plasticity. This novel modelling expertise complemented materials characterisation work, enabling Tim to make a noteworthy contribution to many publications together with KTH colleagues. (

Diva

)

Tim is now a Senior Researcher at Hamburg University of Technology (

Linkedin

), Hamburg - which is his hometown.

We are pleased to continue to work with Tim in several initatives e.g. the Steel4fatique project.

Tania Loaiza Uribe, PhD, 2024

In February 2024, Tania successfully defended her

PhD thesis

"Microstructural Decay in High-Strength Bearing Steels under Rolling Contact Fatigue".

Tania collaborated with Ovako with the aim to identify the mechanisms underpinning fatique in the mounts of ball bearings. The work conducted in the Center for Mechanics and Material Design (

MMD

).

The microstructures of different materials, which had been subject to various levels of rolling contact fatique, were studied and compared using a comprehensive set of materials characterisation techniques at the

Hultgren Lab

and at synchrotron facilities. The use of multiple characterisation techniques enabled the qualification and quantification of underlying fatique mechanisms as well as the extent of the materials' fatique degregation. Tania developed a strong scientific understanding of the coupling between the microstructural properties of materials and a materials' susceptibility to degregation and fatique.

Tania went on to become a researcher at Ovako, Sweden. (

LinkedIn

)

We are pleased to be able to continue to work with Tania e.g. via Ovako's partnership in the

NEXT

Competence Centre.

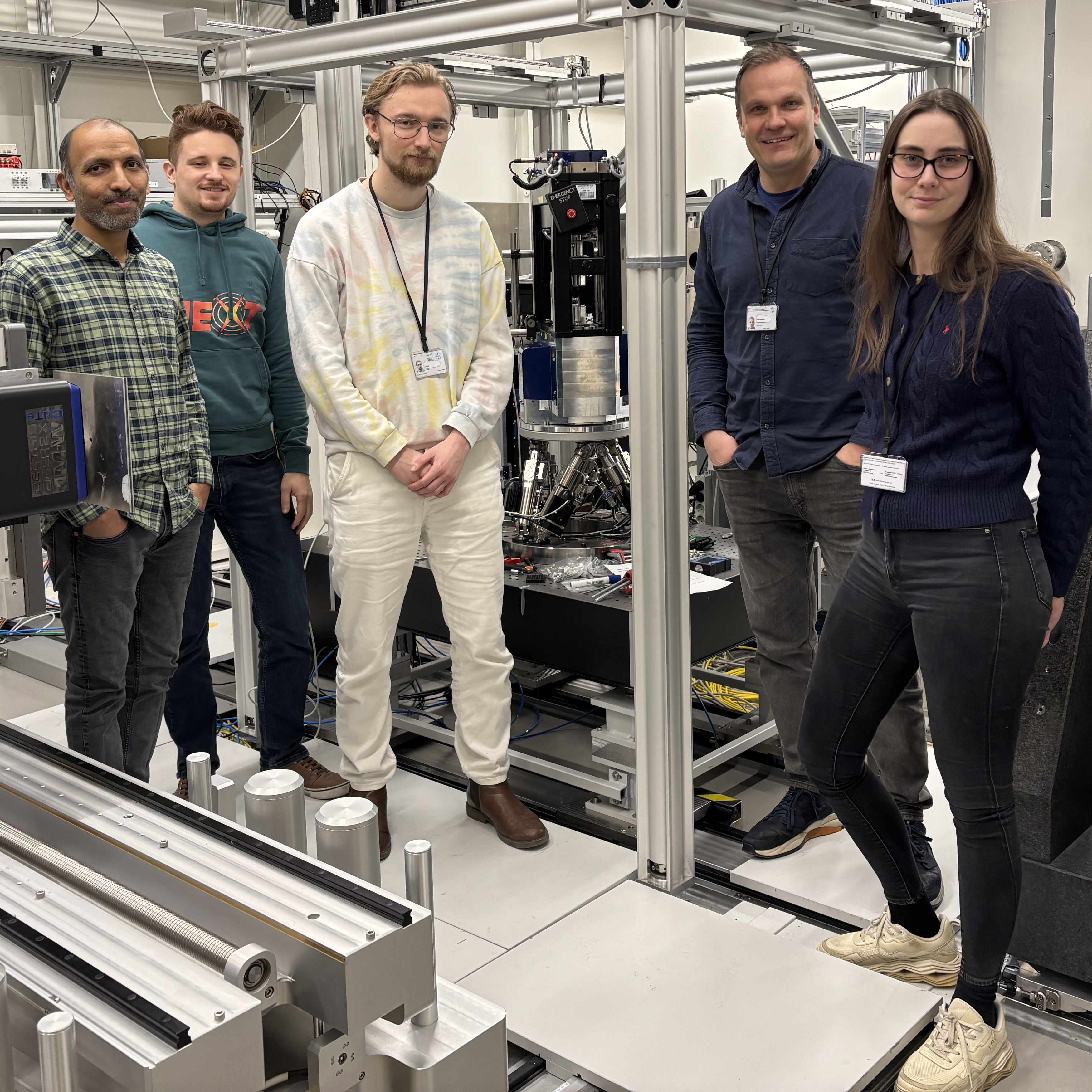

Prasath Rajan, Director of the Hultgren Laboratory

Prasath was the Director of the Hultgren Laboratory, where his expertise in materials characterisation techniques and deep understanding of research was much appreciated by laboratory users as well as students and staff at our unit.

Prasath was offered a senior position at Outokumpu (

LinkedIn

), where he now works with research and innovation activities.

We continue to collaborate with Prasath on individual projects as well as activities within the

NEXT

Competence Centre, where Outokumpu is a partner. For example, this photograph, which shows Prasath of the left, is taken at a beamtime experiment. That experiment also involved one of our post docs, two masters thesis students and the unit manager.