Powder Characterisation

The Powder Characterisation Lab at the Unit of Process is developing innovative ways to measure properties of powders and supports the other research activities in powder metallurgy. The lab offers a wide variety of traditional and novel characterisation techniques and polymer 3D printers.

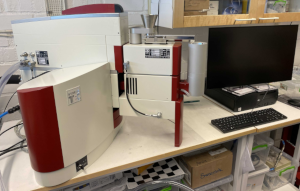

Freeman FT4 Powder Rheometer

A relatively recent innovation in powder flow testing, powder rheometers are capable of simulating a range of stress states and flow conditions and measure force and/or energy required to achieve flow under the selected conditions. The KTH Powder Characterisation Lab is equipped with a Freeman FT4 Powder Rheometer with Shear Cell and Aeration Unit, supported by a range of accessories. The rheometer can provide a variety of metrics that give information about powder flowability and density.

Dynamic image analysis for particle size and shape

Particle size distribution and shape metrics are readily measured using dynamic image analysis, in accordance with ISO 13322-2:2021 with a SympaTEC QICPIC, equipped with the corresponding "OASIS" wet and dry powder dispersion module. The machine can measure particles from around \(5\thinspace\mathrm{µm}\) in diameter up to several centimetres. Various size measurements are possible, such as equivalent circle diameter, Feret diameter and chord length; shape metrics include aspect ratio, sphericity and convexity. Typically, around \(10\thinspace{}\mathrm{mL}\) of sample is required for each measurement. A typical measurement takes less than one minute and analyses hundreds of thousands of particles. Analysis is automated and the statistics that are calculated can be selected to suit the needs of the investigation.

Particles can be added to the machine in three ways, each of which has advantages and disadvantages over the others:

- Sprayed using a compressed air stream (best for separating particles, may break fragile particles, cannot recover particles)

- Allowed to fall under gravity (not so good at separating particles, can recover particles, fragile particles more likely to remain intact)

- Dispersed in a liquid medium (more labour-intensive, possible to filter mixture to particles, can measure smaller particles sizes, much slower measurement)

Automatic Sieve Shaker

The KTH Powder Laboratory has a Retsch AS200 Automatic Sieve Shaker to divide samples by particle size and derive a mass-based size distribution using a high-precision balance with integrated data transfer to control software. Up to eleven sieve sizes may be stacked in any one operation, allowing the creation of many fractions with sizes, \(d\), in the range \(20\leqslant{}d\thinspace{}/\thinspace{}\mathrm{µm}\leqslant{}500\).

Spinning Riffler (rotating sample divider)

When testing powders, it is often necessary to divide a large mass of powder into smaller samples. One example is for Hall flow tests, where a sample size of 50 g is demanded by the international standards. The KTH Powder Characterisation Laboratory, has a machine from Haver & Böcker specifically for this purpose. It divides samples continuously into ten containers. After the division is complete, the ten samples should have very similar masses, size distributions, shape characteristics, etc. The machine can divide samples up to several kilograms.

Tap density tester

To investigate the settling behaviour of powders, the KTH Powder Characterisation Laboratory has a Quantachrome Tap Density Tester that fully meets international standards for tap frequency and amplitude. There are many measuring cylinders available for use with the machine.

See this slow-motion video of the tap density tester (opens in KTH Play) in use at the KTH Powder Characterisation Lab.

Hall/Carney Flow Funnel and Apparent Density tester

One of the most widely-used powder testing methods, the first piece of equipment added to the KTH Powder Characterisation Laboratory was the Hall Flow funnel with an additional Carney funnel and apparent density testing cup.

50 g of powder is loaded into the funnel while the funnel is blocked. The funnel is unblocked and a stopwatch is started. When the powder has finished flowing out of the funnel, the stopwatch is stopped and the time is recorded. The apparent density cup fills with powder and this powder is then scraped level with the top of the cup. The cup has a known volume of 25 ml and this is used to calculate the apparent density of the powder.

See this video of a discrete element model (DEM) simulation of the fill-in god a Hall flow funnel (opens in KTH Play) identical to the one pictured (available in the KTH Powder Characterisation Lab).

Thin film applicator

Many additive manufacturing processes are based on the powder bed geometry, where powder is deposited in thin layers. Of course this requires that it is possible to spread the powder into thin layers but there is no accepted test to measure this. KTH Powder Characterisation Laboratory has invested in a thin film applicator to develop such a test.

Current work is focusing on three aspects of the test, in collaboration with our colleagues at Swerim AB and a range of powder producers in Sweden:

- How should the powder sample be dispensed prior to the test?

- What metrics should be considered to determine the spread behaviour (spreadability) of the powder?

- How should these metric be recorded?

Angle of Repose meter

Another common, traditional method to measure flow behaviour, the static angle of repose test involves powder falling from a fixed height and make a pile on a horizontal surface. The angle of the pile indicates the flow: a higher angle suggest poorer flowability. KTH Powder Characterisation Laboratory has this test available.

Environmental Monitoring

To ensure safety of lab users and investigate the impact on air quality caused by powder handling, the KTH Powder Characterisation Laboratory is equipped with a sensor to measure the mass of dangerous particles that are in the air. This sensor unit also records temperature and humidity. An independent temperature and humidity sensor is also used to monitor ambient conditions in the lab.

3D printers

KTH Powder Metallurgy is currently supported by three polyer 3D printers, the newest two of which were purchased in December 2025. The current printers support teaching and provide a prototyping or rapid production capacity for our research.

A Bambu Labs H2C polymer fused deposition modelling (FDM) printer is available in the Powder Characterisation Lab. This printer is used to create rigid solid parts for teaching or research purposes and is capable of printing a component with up to four different filaments, any two of which can be used simultaneously. The maximum print size is \(330\;\mathrm{mm}\times{}320\;\mathrm{mm}\times325\;\mathrm{mm}\). The printer also features a laser cutting module to engrave features into a part surface. A smaller Bambu Labs P2S printer is also available to print smaller parts up to \(256\;\mathrm{mm}\times{}256\;\mathrm{mm}\256\;\mathrm{mm}\). Both printers offer automated filament changing during print jobs. Båda skrivarna erbjuder automatisk filamentväxling under pågående utskriftsjobb.

In addition, a Formlabs Form3 stereolithography (SLA) printer is available, belonging to the KTH Unit of Processes. It can produce both rigid and flexible parts up to \(145\,\mathrm{mm}\times{}145\,\mathrm{mm}\times{}185\,\mathrm{mm}\) with a vertical resolution of 85 µm and a horizontal resolution of 25 µm.

Metal powder bed melting 3D printers are available at KTH, both at the Department of Materials Science and Engineering and elsewhere.