Casting and Solidification

Casting and Solidification focuses on fundamental experimental and theoretical research that is of relevance to all types of industrial casting och solidification processes.

By combining innovative experimental techniques, mathematical modelling and numerical simulation, the aims are:

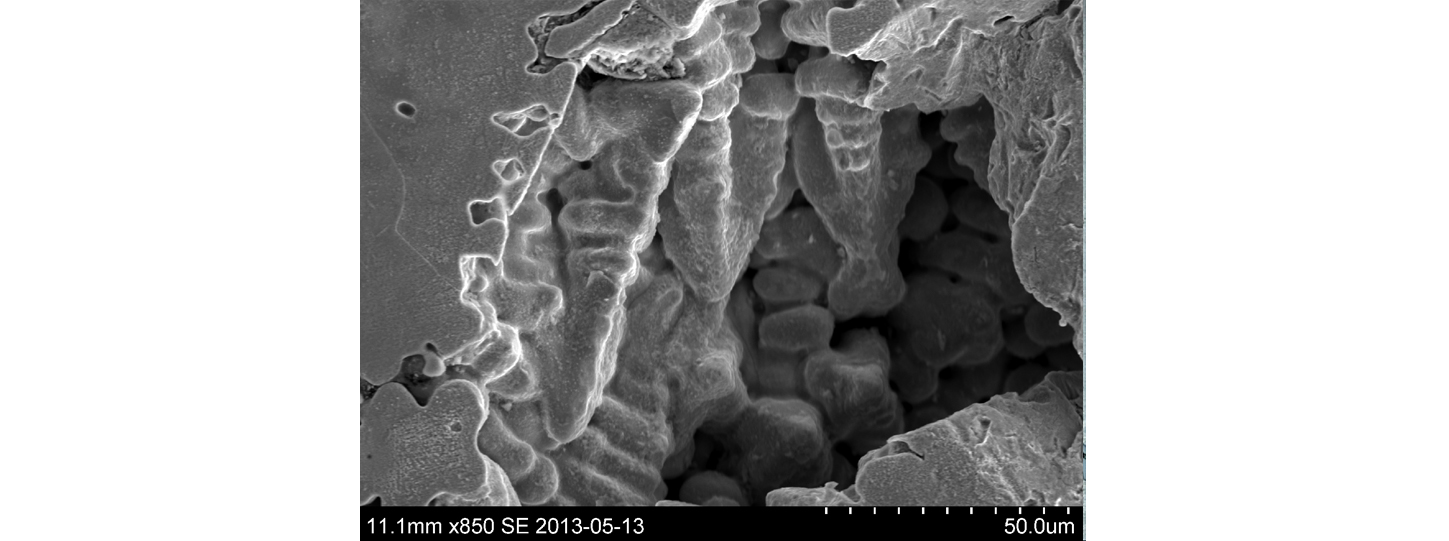

- Understanding the complex interaction of the physical phenomena – solidification, heat transfer, fluid mechanics, phase transformations, thermal stress - that occur during casting;

- Addressing industrial needs to minimize structural defects – oscillation marks, cracks, tears, macrosegregations, pores, inclusions - that occur during casting;

- Improving the design of existing casting processes, and suggesting designs for new ones.

Although the main focus is on the ingot and continuous casting of steel, other types of processes, e.g. high-pressure die casting, and other types of alloys, e.g. copper- and aluminium-based, are also considered. Moreover, and with a view to acquiring the knowledge to minimize defects in cast material still further, we seek to expand the research activities to address what happens immediately upstream and downstream of the casting process itself: melting and heat treatment, respectively.