Sintering non-homogenous structures to enhance performance: sub-project (work package) on characterization

Background

Composite materials consisting of a hard ceramic phase and a ductile metallic binder phase are generally called hard metals (HM) and they often have a very attractive combination of high hardness and toughness. One group of HM is cemented carbides, which traditionally consist of tungsten carbide (WC) as the hard phase and cobalt (Co) as the binder phase. Furthermore, additional hard phases (cubic carbides and/or carbonitrides) are often added to improve hardness. Cemented carbides are manufactured via a powder metallurgy (PM) processing route which opens up flexible production and novel concepts can be implemented more efficiently than in ordinary casting metallurgy. Today methods are available that allow for tailoring of PM materials’ properties locally, thus creating a gradient in properties, so-called functionally graded materials. State of the art in HM processing is to manufacture homogenous PM alloys, i.e. with the same structure and properties everywhere in the material, but there are also examples where gradients have come to use, e.g. in certain HM grades for steel turning. The gradient zone is at the surface of the HM, typically 10-30 µm that has a modified microstructure. This gradient zone can be created by an inactive sintering (i.e. in vacuum with no gas atmosphere) process. The result is a tougher surface zone and a harder bulk. Alternatively, by using active sintering (with a gas atmosphere), gradients with other properties can be created.

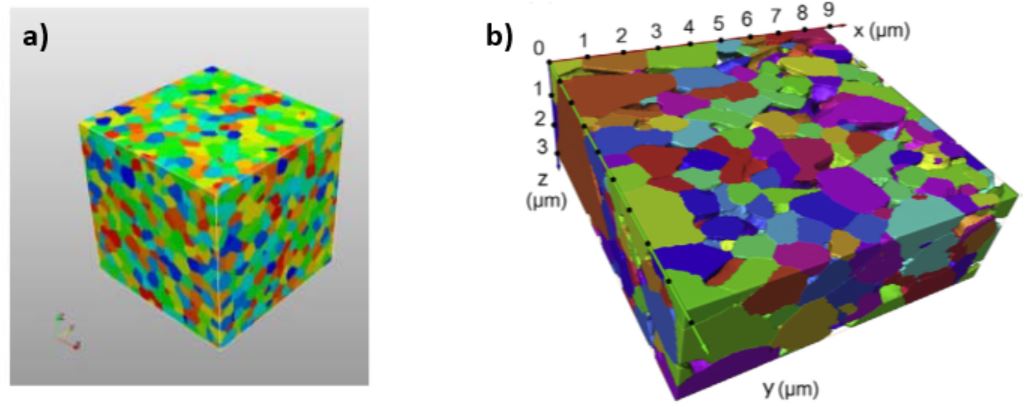

One new general development within powder metallurgy that will have a major impact also on the cemented carbide area is 3D printing with the possibility to produce e.g. prototypes without huge infrastructure investments etc. In this project, the possibilities to build green bodies with different functional powders locally enabled by 3D printing or multiple filling of powders in the press cavity will be utilized together with novel technologies for surface-modification of powder raw materials and for controlled sintering of non-homogeneous cemented carbide components. This activity will be carefully guided by 3D materials modelling and experiments (Fig. 1), according to the concept of integrated computational materials engineering (ICME).

Purpose and aim

The overall goal of this initiative is to form a basis for future development of sintering technologies for the manufacturing of powder metallurgical composite materials. Materials with non-homogenous properties represent a huge potential to enhance performance. This applies to manufacturing of hard metals in particular and hold promises of enhanced performance e.g. in metal cutting and rock drilling.

Project plan

In the present proposal, we intend to create functional gradients by modifying the so-called green body (the material after pressing/shaping) and, furthermore, to fine-tune the local properties during sintering. Such gradients can be created in different ways, e.g. by the use of multiple powders with different compositions that will allow multiple functionalities in the as-sintered product. The modification of the green body can thus be performed using a free-forming technique followed by a sintering step in which the furnace atmosphere is carefully controlled. Another way to create gradients is to modify the powder raw materials themselves e.g. using the sol-gel technique.

The present project methodology is based on an ICME approach to reach the goals. We will thus guide the experimental work with modelling efforts ranging from atomic scale to continuum mean-field modelling such as the phase-field and the sharp-interface methods. The research program is divided into five work packages:

WP 1: Sintering of modified raw materials

WP 2: Sintering of multiple powder green bodies

WP 3: Sintering of multifunctional components

WP 4: Characterization of sintered materials.

WP 5: Mean-field and atomic scale interfacial modelling.

Whereof, the sub-project described here relates mainly to WP 4, where characterization of the sintered components, and when needed the raw material powders and green bodies from WPs 1-3, will be conducted. The experiments will be used to verify the achieved structure and properties and provide a basis for coupling model sintering parameters to theory and microstructure. The characterization will mainly be based on electron microscopy in 2D and 3D, atom probe tomography (APT) as well as X-ray diffraction. When high-throughput or in-situ data is needed, synchrotron X-ray microscopy and scattering, and neutron scattering will be utilized.

KTH, Chalmers and Sandvik are partners of this project.

Funding agency

SSF.

Beginning and end dates

2016-01-01 to 2022-06-01

Project contacts

More information

N/A