Recovered electronics reduce carbon footprint

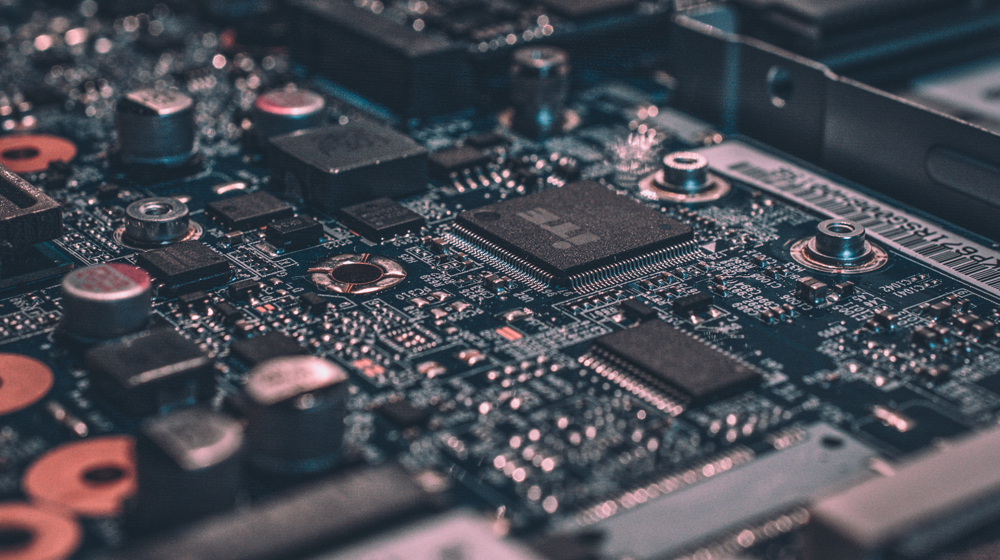

Waste from electrical and electronic equipment (WEEE) is estimated to grow to about 12 million tons by 2020 in EU, which makes it the fastest growing waste stream. By mixing recovered WEEE in metal production, the carbon footprint decrease considerably. WEEE also contains more than 30 % of plastics, which can be a useful source of chemical feedstock and energy.

Energy recovery of organic matter is estimated to around 21.4-23.6 GJ/ton of WEEE which leads to about 1530-1670 TJ/year if all the energy is recovered. In addition WEEE being a mixture of various materials can be regarded as a source of ordinary metals (Cu, Al, Fe, Pb, Zn) as well as precious metals (Ag, Au, Pt, Pd) and rare metal elements (Ta).

It is well known that the energy consumption for metal production from recycled source is much lower than the production from primary ore. The energy savings from WEEE contained metals are around 1.6-3.25 GJ/ton of WEEE or 114.7-179.25 TJ/year. This means 5-15% increase in overall energy efficiency and reduced carbon foot print for the metal production.

Recovering energy and materials from waste including WEEE can make sustainable development of the industries.