INEVITABLE

Optimization and performance improving in metal industry by digital technologies

The project INEVITABLE is targeting at resource and energy intensive sectors of the process industry, with focus on the steel and nonferrous metals sector.

Since these industries have an enormous impact on energy and resource consumption, and consequently on the environmental footprint, improvements of energy and material efficiency represent major results of the project with positive impacts on both process sustainability and environment.

The focus of INEVITABLE is to develop high-level supervisory control systems for different production plants and to demonstrate them in operational environment to enable autonomous operation of the processes based on embedded cognitive reasoning.

The project approach is based on three enabling technological areas:

- data collection & sensor technologies,

- tools for data analysis, control and optimization,

- digitalization infrastructure;

The application of these enabling technologies will be an important step towards digital transformation and optimization of selected production processes (link to external webite).

To get updated with project news, subscribe to the newsletter (opens blank email in your default email client).

You can find out more information about INEVITABLE by visiting the project homepage (link to external website).

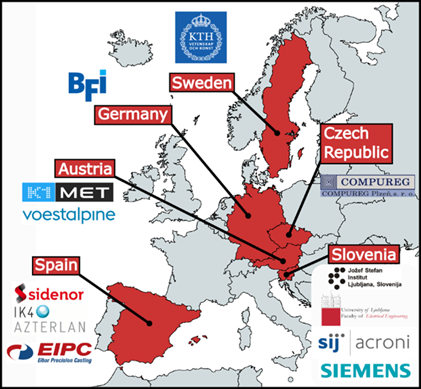

INEVITABLE is a collaboration across many European countries.

INEVITABLE has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 869815.