Sustainable technology for the staged recovery of an agricultural water from high moisture fermentation products

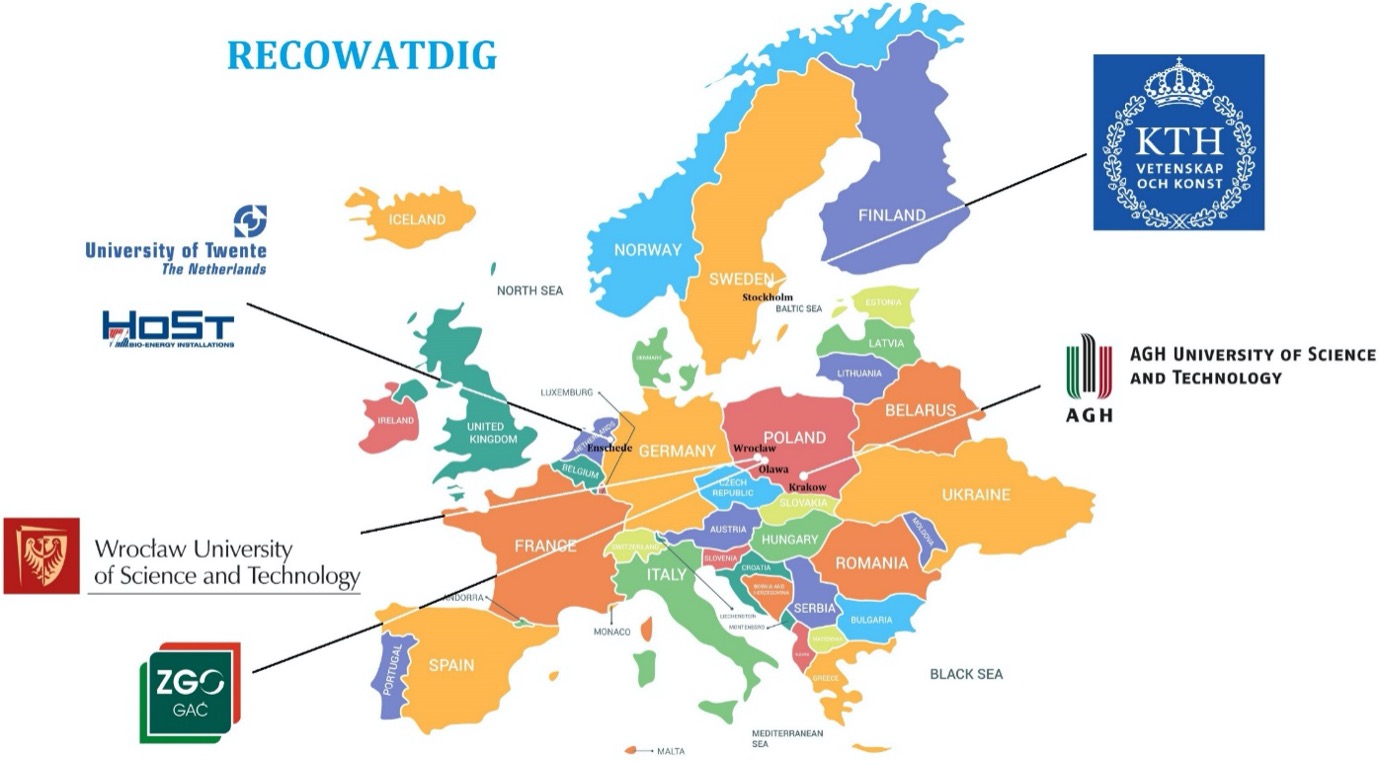

RECOWATDIG

Proposed concept is to treat solid waste residence from AD-anaerobic digestion by HTC following by pyrolysis process, the hydrochar generated from pyrolysis will be further modified as magnetic performance thus can be used to treat waste water. Proposed technology will be modular and transportable, i.e. technical design will include containerization of all of the modules.

Project proposes innovative, trans-disciplinary approach, by enabling the access to the potential water resources, currently neglected, i.e. water evaporated during drying of high moisture solid fermentation products. Moreover, project is aiming to achieve the effect of synergy, by improved heat balance of the drying process, by utilization of the latent heat, that could be recovered during the recovery of water through condensation. Furthermore, project proposes using hydrothermal carbonization (HTC), with additional potential for synergy due to expected positive effects in terms of initial dehydration and sanitization. Purification of the water from two separately obtained streams will be achieved by the use of different types of membranes selected in a way that will optimize the use of the electricity by the installation as well as CAPEX and maintenance cost. The use of electricity will be further optimized by implementation of accumulation of pure water, allowing to minimize the cost of electricity by using it during off peak hours. This will make the proposed technology “smart grid ready”.

Funding agency

Formas, Era-Net Water JPI program

Start and end dates

1 March 2019 - 31 December 2022

Contact person